Brass mini hinges

Page 1 of 1

Brass mini hinges

Brass mini hinges

this is the way i make them

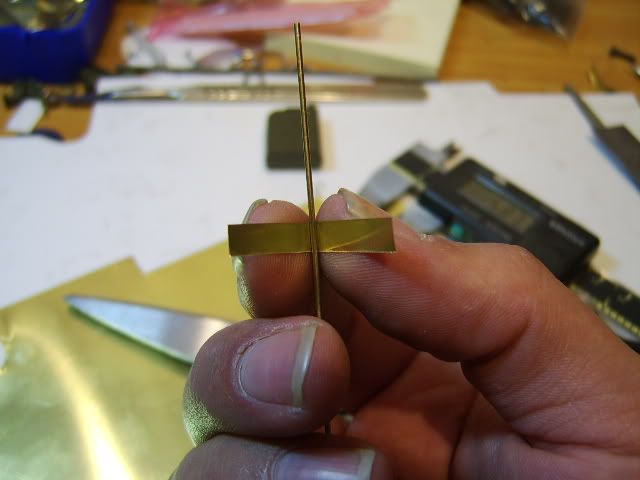

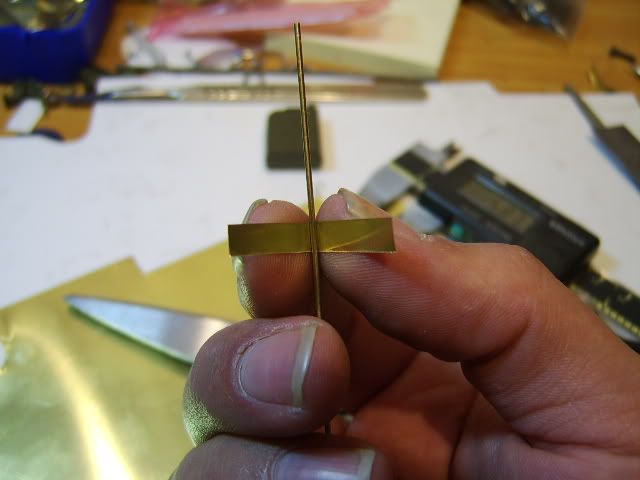

First up the material used is 0.1mm brass sheet this isn't the norm but you will need to guage the thickness for your own needs

the bigger the hatches/door the thicker the sheet and tube/rod the thickness of the former (rod/tube) depends on the size of the original

next is to measure the hinge to be replaced

then look at the original and see what it looks like and what type your going to build (this one has a 3 position hinge similar to a door hinge)

measure the hinge and transfer it to the brass sheet and cut out the strip you'll need two strips for one hinge

fold the strip around your rod/tube and clamp firmly with pliers creating the nice round

tube

More to follow

First up the material used is 0.1mm brass sheet this isn't the norm but you will need to guage the thickness for your own needs

the bigger the hatches/door the thicker the sheet and tube/rod the thickness of the former (rod/tube) depends on the size of the original

next is to measure the hinge to be replaced

then look at the original and see what it looks like and what type your going to build (this one has a 3 position hinge similar to a door hinge)

measure the hinge and transfer it to the brass sheet and cut out the strip you'll need two strips for one hinge

fold the strip around your rod/tube and clamp firmly with pliers creating the nice round

tube

More to follow

fv432- Be nice to me I am new

- Posts : 38

Join date : 2012-10-25

Age : 54 Location : Great britain

Location : Great britain

Re: Brass mini hinges

Re: Brass mini hinges

once you have the basic shape put it in a helping hand and carefully solder the edges together to stop it coming apart(don't go to far up or you'll solder the rod/tube to the hinge Not good)

clean of any remaining solder so it's nice and flat and pop it in a vice (i use ally angle as it keeps a nice sharp edge)

remove the rod/tube and mark up the hinge to look how you want it then carefully dremel/file out the waste clean of the burr and re-try the rod/tube

now you have one hinge side follow the same steps for the other side and align the two parts and mark off the waste on the other side and cut out the same as the first. try it with the other side and see if it fits a bit of careful fileing dremaelling and alls good to go fit the rod/tube to the two parts and now you have your own scale hinge

some of my hinges on my tanks

clean of any remaining solder so it's nice and flat and pop it in a vice (i use ally angle as it keeps a nice sharp edge)

remove the rod/tube and mark up the hinge to look how you want it then carefully dremel/file out the waste clean of the burr and re-try the rod/tube

now you have one hinge side follow the same steps for the other side and align the two parts and mark off the waste on the other side and cut out the same as the first. try it with the other side and see if it fits a bit of careful fileing dremaelling and alls good to go fit the rod/tube to the two parts and now you have your own scale hinge

some of my hinges on my tanks

fv432- Be nice to me I am new

- Posts : 38

Join date : 2012-10-25

Age : 54 Location : Great britain

Location : Great britain

Similar topics

Similar topics» A new mini diorama base from Mini-Art

» Jennys Build : Dragon Marder II ALL FINISHED SEPTEMBER 6th !!!!!!

» Eduards latest brass bits.

» New from MiniArt

» New from Mini Art

» Jennys Build : Dragon Marder II ALL FINISHED SEPTEMBER 6th !!!!!!

» Eduards latest brass bits.

» New from MiniArt

» New from Mini Art

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum